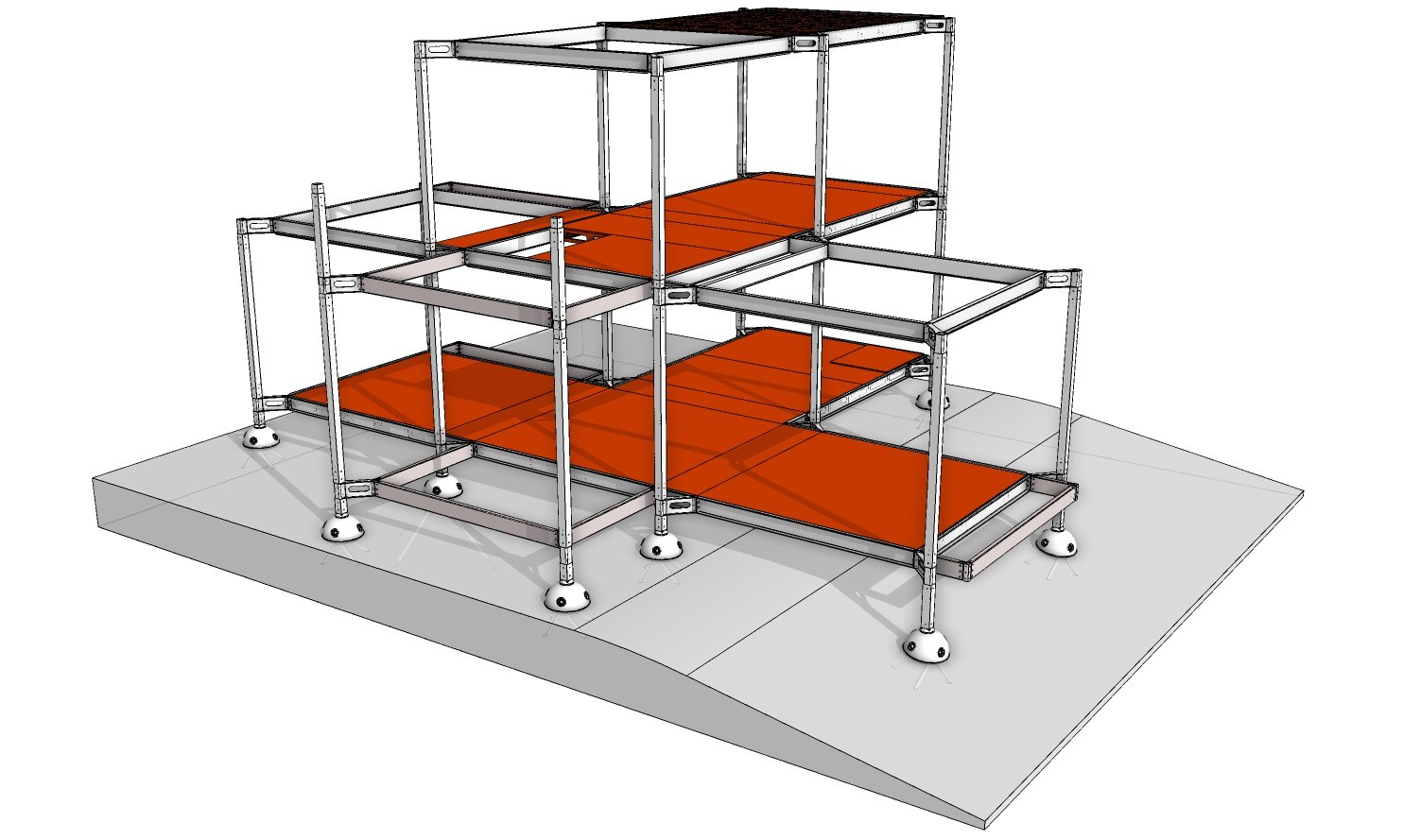

How the PAKHAUS system works

PAKHAUS is an innovative modular construction system designed to address inefficiencies in traditional building methods. It prioritises adaptability, transparency, and reusability, offering a solution for projects requiring quick assembly, high customisation, and eco-conscious construction.

Suitable for a wide range of applications—from residential and commercial spaces to industrial and research facilities—the system is engineered to minimise on-site disruption and maximise design flexibility.

[ noted features ]

[ modular and adaptable ]

PAKHAUS structures are highly customisable, allowing easy expansion and configuration to meet diverse needs. At the heart of of the PAKHAUS principle is use of the latest in technology to fabricate, manipulate and operate the structure. PAKHAUS are easily upgraded and adapted as usage requirements change.

[ prefabrication reliability ]

Components are produced in controlled factory environments, ensuring quality and precision. Controlling the fabrication process is made easier by using established manufacturing facilities, locally manufactured with local materials where possible. Prefabricated assemblies “Pods” (e.g., bathrooms, kitchens) arrive fully assembled.

[ scheduling ]

PAKHAUS are assembled from a number of pre-designed and pre-fabricated components, with the customisable elements being the simpler, lighter items that form the “Live-able Units”. These units are typically based on traditional manufacture techniques and are made in the PAKHAUS factory. Weather does not effect the manufacture and assembly of the structures. The installation of a PAKHAUS structure on a typical site can be achieved in days, not months, depending on conditions.

[ efficient assembly ]

Small teams can assemble the structures using minimal equipment, notably HIAB equipped flat-bed trucks and/or spider cranes, with the preference to avoid the use of heavy machinery like cranes. The PAKHAUS outer framework supports on-site adjustments and future expansions while doubling as its own lifting system when required. The majority of the components are prefabricated as completed items. The in-built limitation of using smaller vehicles and their attending small teams ensures the assembly process is respectful of local environments, regardless of location and access.

PAKHAUS offers a number of installation solutions. Owner assembled, Partially Assembled,

[ future adaptable ]

Technology plays an integral part in the development and evolution of the PAKHAUS System. From the original designed concept, implementation of manufacturing processes, to handling and installation, through the usable lifespan and interaction with the structure and its eventual repurposing, technology ensures the PAKHAUS purpose is maximised.

The PAKHAUS website provides an connection between the structure and the supplier, with every component being coded and every structure being documented with asset lists and assembly and installation schedules.

[ cost effective ]

PAKHAUS will never expect to be cost-comparable on day-one of its sale. The recent uptake of “Tiny and Flat-pack buildings” share one particular negative feature; the perceived need to be cheap. This leads to products with a rapid rate of degradation, leading to diminishing quality of use and a short life-span before destruction, or complete renovation. PAKHAUS expects any structure to maintain 95% effectiveness over its lifespan. The 10% loss is expected to be the retirement of internal fixtures, out-dated technology and the natural erosion of materials.

[ transparent cost management ]

A clear and straightforward system allows every component to be identified, tracked, and modified without hidden costs. To ensure effective communication between PAKHAUS and the client, all projects are visualised and provided as an itemised document via a unique webpage.

[ environmental impact ]

No product can be fabricated without acknowledged impact on the world, whether by the use of materials or services, all manufacture requires something to be taken from the Earth. PAKHAUS proposes to offer a product that maintains its usability for any number of lifespan cycles. Reuse by effective quality, not quantity. By supplying a high-quality product that doesn’t expect recycling or destruction at the end of use.

The intention is that any PAKHAUS structure would be manufactured with a conscious respect for minimising waste and limiting potentially negative environmental factors.

[ principles ]

[ research ]

Comprehensive data collection and analysis ensure reliable, efficient solutions. Material use and manufacturing technologies. Energy use. Manufacturing practices.

[ transparency ]

Every process and component is understandable and traceable, fostering client trust. How does PAKHAUS operate. Does the client readily understand the PAKHAUS obligation and commitment.

[ simplicity ]

Straightforward designs minimise complexity while maintaining functionality. A well designed product speaks a simple language. A product that is easily used determines how the product creates connections with the user.

[ discipline ]

Adherence to structured design principles ensures adaptability and consistency. The PAKHAUS structure is an excellent paradigm for discipline, referring to strict adherence to proportions and manufactured excellence.

[ energetic ]

The PAKHAUS brand will never accept bland or average and disguises complexity behind considered elegance.

[ value ]

In deference to a majority of manufacturers, PAKHAUS aims to retain a high resale value at the end if its life span.

[ key innovations ]

[ grid-based design ]

Inspired by traditional architectural specification like the “KEN” proportions of Japanese architecture, PAKHAUS uses a standardised grid for consistency and cost-efficiency.

[unique exterior framework ]

An outer structural frame separates from lighter internal structures, allowing non-load-bearing walls for easier assembly and reconfiguration.

[ customisable add-ons ]

Optional features like balconies, pergolas, and high-end finishes enable personalisation.

[ sustainability focus ]

Components are designed for reuse and recycling, reducing waste and extending lifespan.

[ clarity of purpose ]

PAKHAUS is a minimalist system by strict design. Offering a direct and obvious solution for structural requirements - yet allowing for personalised, harmonious results.

[ unique advantages ]

[ versatility across industries ]

One structure design suits any number of situational requirements.

[ visually dramatic ]

The typical PAKHAUS structure uses a dynamic external structure that can be presented as the client’s customisation requires. PAKHAUS describes a visual, graphic language. The assembled forms have historical precedence in traditional architecture and graphic design.

[ component effectiveness ]

The ability to effect adjustments, updates and repairs without destruction or depreciation of the structure or installed components. PAKHAUS utilises component isolation to eliminate cross-component degradation.

[ true adaptability ]

Unlike many structural systems that are limited to fixed designs, PAKHAUS offers flexibility across various structure types. Its modular components ensure long-term usability and adaptability, outperforming prefabricated systems that often require extensive site preparation and heavy machinery.

[ truly reusable ]

The PAKHAUS system is based on a common sizing grid. Although not imperative this system makes the option for reuse of the individual components.

[ honest recyclability ]

It is a central tenet in the philosophy of the PAKHAUS design system that ALL components must reused and/or recycled with ZERO waste. This is very difficult but is achievable when considered carefully.

[ highly predictable ]

The PAKHAUS system is based on common items and common design processes. This makes the process of design and updates easy to understand and predict.